Power + Thermal Layer: Why Cold Matters

Cold climates offer cooling advantages — but don’t hallucinate this into “free energy.”

Compute Cooling

Advantages

- More hours of economized cooling — “Free cooling” from cold ambient air

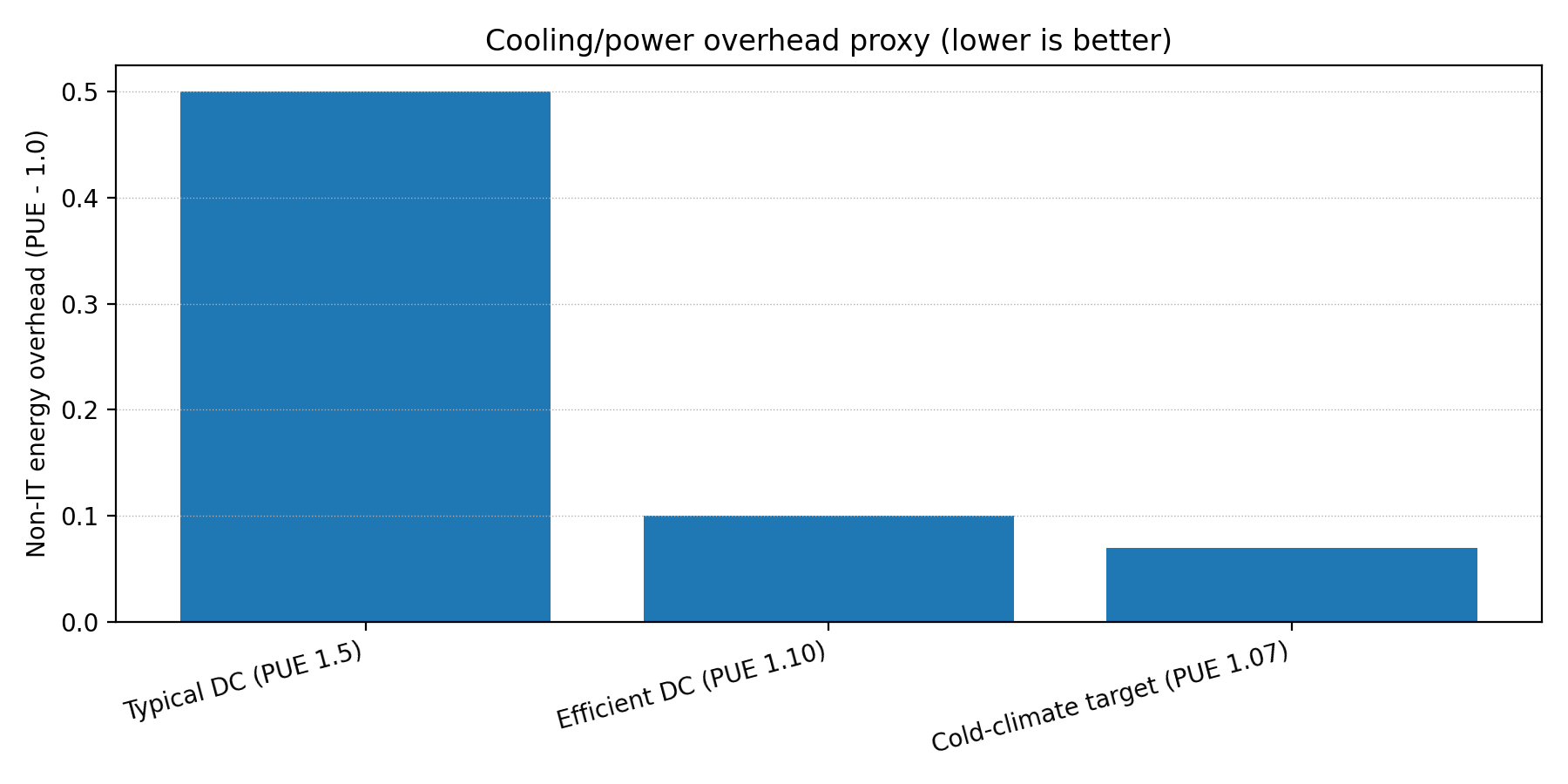

- Lower PUE — Power Usage Effectiveness improves with reduced HVAC load

- Stable heat rejection — Consistent cold sink year-round

Constraints

You still need:

| Requirement | Why |

|---|---|

| Reliable generation + transmission | Grid stability in remote locations |

| Redundancy (N+1 / 2N) | Critical nodes cannot fail |

| Humidity control | Cold air is dry → ESD risk, material constraints |

Fab Cooling (Semiconductors)

Advanced fabs are dominated by cleanroom HVAC, filtration, and strict temperature/humidity stability.

Cold Climate Benefits

- Reduced lift — Less work per unit heat removed (chiller efficiency)

- More stable heat rejection — Consistent condenser performance

Cold Climate Constraints

- Tight internal control still required

- Per-wafer water requirements remain substantial

- Cleanroom HVAC recirculation dominates energy

Don’t confuse “cool air” with “cheap fab.”

Water Requirements

Semiconductor manufacturing consumes large volumes of ultrapure water (UPW):

| Process | Water Impact |

|---|---|

| Wafer cleaning | High-purity rinse cycles |

| Chemical preparation | Dilution and mixing |

| Cooling | Process and facility cooling |

Winter operations: Water intake and treatment must handle freeze/thaw cycles.

Waste Heat Reuse

In cold regions, waste heat from data centers is a resource:

Data Center Heat Output ↓ Heat Exchanger ↓ District Heating Grid ↓ Community Buildings / GreenhousesThis converts “cooling cost” into “community heat,” improving overall system economics.

Key Metrics

| Metric | Target |

|---|---|

| PUE | < 1.2 (with free cooling) |

| WUE | Minimize, track year-round |

| Heat recovery | > 50% to district heating |